Advertised on ebay (uk) as not working I won the bid and took my chance with this purchase.

I could see that the VU meters were problematic, and indeed upon opening up the meter casing I could identify that the left channel VU meter had its loading/return spring partially buckled.

An attempt was made to salvage the VU meter by very carefully de-buckling the return spring and then strengthening the weak area with ultraviolet light glue - the process worked very well. So now both meters work.

|

| The VU Meters before they were partially repaired. |

Initial Findings

Before any work on the meters was done, the machine arrived near 'dead' - the meter lamps lit up, but nothing else happened.

For anyone not familiar with the RD 4600, I'll issue a warning - this cassette deck is not 'repair friendly'. It took me some time to decipher how open up the machine.

Power Supply Unit

Observing the PSU, it was noted that a push-on cable had come away and returning this to its intended point, the motor began to rotate! At last, the deck was 'alive'.

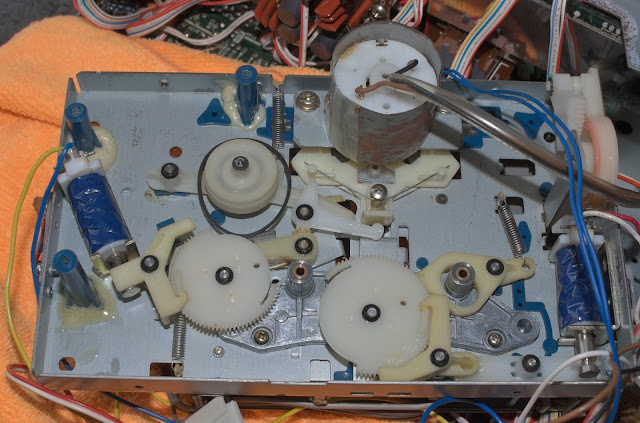

At this point the deck would playback tapes, although take up spool torque was low, and RW/FF didn't work consistently. These faults were soon taken care of via disassembly of the cassette transport and cleaning.

The next and obvious job was to re-populate the PSU with new electrolytic capacitors.

|

| Sanyo RD 4600 PSU, and Bias Oscillator Board. Image shows the unit partially re-capped. Later - many of the other components were also replaced. |

This board not only acts as a power supply unit (PSU), but also for two sources of DC supply voltage - a regulated supply at about 19v, and nonregulated at about 24v.

The said board also contains the bias oscillator, bias current control to match bias to the tapes, and a bias trap. The purpose of the trap is to filter out the bias high frequency and relatively high bias voltage from the audio circuits.

Play Mode

In PLAY mode, the deck would sometimes not operate - one source of this problem was a sticky PLAY solenoid. All mechanisms were cleaned with IPA and a Servisol Super 10 equivalent.

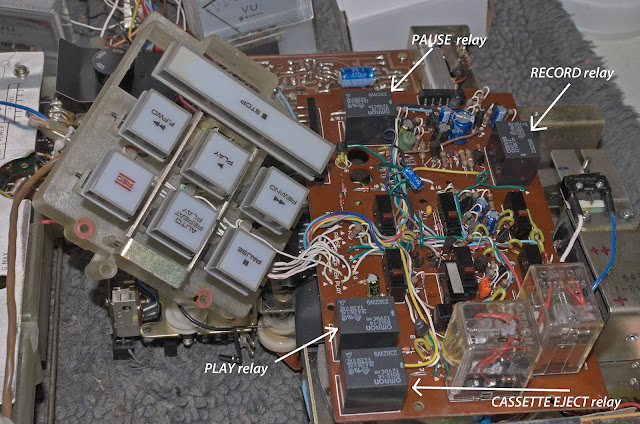

Another issue that surfaced was that pressing PLAY didn't always activate the full driving voltage (approx 12v DC) across the solenoid to operate the PLAY mechanism. I originally thought there may be a problem with the solenoid, but it transpired that the PLAY relay internal contacts were probably and partially corroded? All relays associated with Record/Play/Pause/Cassette-Eject were replaced.

To identify this, studying the service manual's circuit diagram was neccessary and the returned hypothesis was that relay contacts were probably to blame.

The DC driving voltage for the PLAY solenoid is approximately 12v, but under load conditions this didn't happen? My thinking was that - the relay contacts were offering (internally) high impedance to the circuit. This explained why the solenoid did not activate - too much voltage drop across the corroded contacts, hence not enough current to drive the solenoid.

Record Bias Noise in Right Channel

The original head recorded and played back fine, no problems except that there was low-level, but noticeable random bursts of extra white/pink noise (bias noise) in the right channel.

After studying most or all of the possibilities, it was concluded that the original Sanyo head was faulty; quite why it did this I don't know?, but similar occurances have happened to other hard-wearing heads like - the Sony Ferrite & Ferrite heads.

Gap erosion is a subject that is talked about on the Tapeheads forum, and I'm assuming that this just might be one of the negative 'spin offs' from this?

I was reluctant to swap the head, but I did eventually. The replacement was a (Chinese made?) DYNY62.

Estimation of Record Head Bias Current

Firstly we measure head inductances, the general consensus seems to be - measure at 10Khz, so we have ...

- Sanyo T-159 D5A5: Right~165.8mH, Left~163.2mH.

- DYNY62: Right~126.7mH, Left~120.5mH.

From this, the head impedance, and hence AC bias current generated at the bias operating frequency of 100Khz can be estimated.

Making the assumption that bias voltage is about 15v to 20v rms, then ...

From basic Ohm's Law: I = V/Z(𝟂), where the impedance Z(𝟂) is almost exclusively inductive, we can estimate the impedance due to the inductive reactance X at 100,000Hz, and later the bias current.

Bias Current: I ≅ V/X

But X = 𝟂L = 2πfL = 2x3.14159x10^5*L

Where L is the inductance in Henries.

Then for Sanyo (Right Channel) ...

15/(2πx10^5*0.166) to 20/(2πx10^5*0.166), or 144µA to 192µA.

And for DYNY62 (Right Channel) ...

15/(2πx10^5*0.127) to 20/(2πx10^5*0.127), or 188µA to 251µA.

These bias current are low by default and comparing, they are not radically different.

The effective impedances at audio frequencies will be much less, but so too will the audio signals. Typically, audio AC voltage signals will be in the µV range, and possibly a few mV at higher frequencies due to recording pre-emphasis.

|

| Original Sanyo T-159 D5A5 Record/PB Head. |

|

| New DYNY62 REC/PB Head During Testing |

Fitting the head was not so simple, the original Sanyo head and platform screw holes are postioned differently from other 'standard' two-head cassette decks. The rightmost new head's guide hole had to be elongated by about 1mm before a near centre line for the head could be established. In fact, more work may be done on this later. Head penetration is unaffected.

Wow & Flutter (Initial tests)

With the original pinch roller, wow & flutter figures as measured by WFGUI indicate figures almost consistently under 0.08% wrms.

TDK D46 Initial Tests

These indicate the record/playback frequency response at -20dB (ref: 0VU) is better than 40Hz to 15,500Khz (±3dB). And Total Harmonic Distortion at +6dB (Ref: 0VU) in the region of 1%. (I will update these figures when the machine is considered to be completely restored)

Before a 'new' head was fitted, the audio board was almost completely re-capped, and most of the original NPN and PNP transistors were replaced by KSA1845-FTA/C1815-GR/2SA992/2SC2001 types where required.

|

| Work was be done on a soft surface to avoid damages and scratches. Here I've used an old clean carpet mat. |

.jpg) |

| Main Audio Board. Also, the mains transformer area is highlighted, and adjacent pre-emphasis circuit. (See comment below) |

Warning: while the electronic design is very good, the audio board layout is poor in my opinion - too many components in such a small area made de-soldering difficult. Sanyo obviously just wanted these units sold!

It is recommended that anyone undertaking such work must use an efficient and accurate de-soldering gun/station.

Azimuth and playback levels were also calibrated from ABEX/TEAC full track reference tapes. Track height was not investigated, the new and old heads appear to have the same base thickness? Recording and playback to and from other third party machines was satisfactory - no obvious azimuth issues or instabilities.

Tape Type Provisions

The RD 4800 appears to have no provision for high bias tapes, like that of a typical Type II tape. Switching in 'CrO2' on the deck only alters pre-emphasis and de-emphasis; it does not increase bias.

No further testing has yet been done on any 'CrO2' or Type II tape.

Other Refinements Pending -

(1) Extra Transformer Shielding.

Stray 50Hz electromagnetic fields appear to be picked up in the right channel of the recording circuit (but not playback), and I suspect probably during pre-emphasis, as this section is adjacent to the transformer as indicated above.

Observing Fast Fourier Transform plots on the playback noise (tape hiss) the interference is low, it mainly consists of odd-numbered harmonics of 50Hz (ie, 150Hz, 250Hz, 350Hz), but can be heard during very quiet passages.

(2) Higher than expect bass distortion - @50Hz, at 0VU record/playback, THD ~ 3%.

(3) New VU Meter Lighting.

(4) Pre-emphasis tweaking, otherwise known as 'Record EQ'.

Currently, the 'Standard' setting sets more pre-emphasis (ie, high frequency 'lift' above 400Hz) than the 'Low Noise' tape setting - this is not necessarily incorrect.

It is interesting when studying the circuit diagrams to see Sanyo allowing tweaking of pre-emphasis via ferrite cored inductor trimmers and one trimmer resistor for the 'Standard' tape setting.

With the new head in circuit, there is a high frequency rise of about 2dB/3dB starting above 10Khz which drops back to 1,000Hz levels at 15,000Hz.

Fall off after 15,000hz is rapid due to the limitations of the head, tape, tape speed, and restrictions applied from the FM multiplex filter. This rise may be 'smoothed out' if the pre-emphasis 'reasonant' frequency was moved to a higher point, and the associated in-series resistor increased to 'dampen' the Q-factor?

In the circuit below, ferrite core inductor trimmers L102/L103/L104 are adjustable and will alter the resonant frequency of the respective 'series' circuit. Capacitors too can be altered to change the 'resonant' frequency; circuit not yet tested).

From memory, the original Sanyo head returned similar frequency response results.

(4) Peak Level Lighting

Peak levels are often set at around +5dB to +6dB above 0VU, but in the case of this Sanyo, we have a sitiation where the response of a peak is slow, due the nature of the filament lamp. A better solution would be to employ an LED circuit, which is visibly faster acting.

Currently peak indication is set to 0VU, from which I estimate the actual peak is somewhere around +6dB above 0VU. This seems to be a sensible setting for this machine.

Summary

So here is the Sanyo RD 4600 after 35-40 hours work on it, and returned back to its case.

A very classy looking retro deck! However, there is more work to do on this machine.

Refinements: Frequency Response

So back to some of the pending issues, we begin with record-playback frequency response.

With regard to tweaking the pre-emphasis as mentioned above, I increased the value of R319/R419 from 100 ohms to 150 ohms in an attempt to 'dampen' the peak rise above 10Khz. This has partially worked, and after reducing the bias a little, a quick and rather convenient assessment of the Sanyo record-playback frequency response was sought employing FFT on the application of White Noise at approximately -20dB, reference 0VU. The FFT plot is not ideal, but gives a good indication of the ability of the Sanyo.

Taking 1,000Hz as reference, there is deviation of -1dB at 10Khz, which then rises to about +2dB before settling back to 15,500Hz at -3dB. On the bass side, we see that at about 35Hz/36Hz, there is a -3dB drop.

The electromagnetic interference discussed earlier is noticeable at this -20dB plot, in particular the dominant 150hz peak mainly in the right channel illustrated in red. A noise artefact at 20Hz also appears, quite where this comes from I do not know, but possibly from the brushless DC motor?

Low Frequency Audio Distortion

An irritating, but not-so-obvious problem with the audio was the low-frequency audio distortion that I percieved during subjective listening tests. This manifested itself as 'muddy' sound.

Several ideas came to mind as to the potential sources of this unwanted sound artefact. They were - (a) improper PB pre-amplifier biasing, (b) faulty muting transistors, (c) the record-playback multiswitch, or (d) the record head.

My first attack was to eliminate (c), the record-playback multiswitch. I knew this was going to be a risk when attempting to resolve the issue.

This 26-holed switch was very carefully de-soldered using a suction-based de-soldering station, and then removed from the board. The circuit board was then cleaned, but the job of opening up the switches (L-ch and R-ch) was a little intimidating - they are so easy to break.

With thoughtful and careful application, the job of cleaning or re-newing these two switches was done.

|

|

Multiswitches for Left and Right Channel - Resoldered into Audio Board. Full circuit board clean was done later. |

Some 3 hours of work went into the job, but the improvement was only slight.

Next on the list of possible sources of the 'muddy sound' were the muting transistors.

Labelled as Q114/Q214 on the schematic, these were initially replaced by 2SC2001. The thought had crossed my mind that I may have inserted the said transistors incorrectly?, but not according to the board layout as described in the service manual. Nor did I doubt the 'pinout' schematic for the 2SC2001 NPN transistors.

With the muting transistors removed, I went throught the process again of testing the sound.

Result? - postive!, no more muddy bass sound, no more mild mid-range 'stress' and treble came to life!

Distorton Figures

Tape: TDK C-46

Again, returning to the spectrum FFT plots, distortion at record/playback at Dolby level was re-estimated.

Third Harmonic Distortion is commonly defined by ...

At 100Hz at Dolby Level

Only two harmonics of the fundermental in question were taken, since the affects of remaining spectra are negligible. The relative differences of the harmonics were estimated using FFT analysis.

At 1000Hz at Dolby Level

Leaking Transformer Interference

So far, a lot of work has gone into restoring the RD 4600, and although the mild right channel 'hum' (150Hz third harmonic) is a subject to be addressed, essential work on this deck is considered to be finished, at least as far as this blogger article is concerned. If and when additional shielding around the transformer is complete, this will be updated below. (03/09/2024)

Brushless DC Motor Assessment

After finishing returning the filament lamps to the VU meters, the brushless dc motor was examined. Of interest to the reader, here are some photographs.

The Brushless DC Motor

Pre-Emphasis Changes to 'Standard' Tapes

In the pre-emphasis or Record-EQ circuit, the 'Standard' setting is now configured so that it is now electrically the same as the 'Low Noise' setting internally.

Previously the 'Standard' tape pre-emphasis was much greater than the 'Low Noise' setting, which forced a much higher high frequency rise during record (pre-emphasis), thus returning an uneven frequency response. Overall frequency response is now much flatter, but not identical - the Low Noise setting still shows the an after-10Khz rise (see above), while the new 'Standard' setting shows a dip around 10Khz of about 0.5dB to 1dB. Both settings can still be 'tweaked' using the relevant ferrite cored trimmer inductors.

Power Supply Fusing

While the service manual suggests in its schematic a full set of secondary fuses to protect the deck, there were no fuses to be found in this UK model!?

A suitable solution will be found later.

|

| Secondary Transformer Cables. No fuses found on this machine! |

Fuse Solution

Three 20mm fuses holders were later inserted into the power supply circuit. These holders were placed electrically into the secondary side of the transformer.

Later I realised that the middle '800mA' fuse holder was not required, I had made a mistake, so the fuse was removed and the line reconnected within.

AC Transformer Secondary Winding Fuses -

2000mA Orange: In line fuse for the unregulated DC power supply for the DC motor, and relays.

800mA Yellow: In line fuse for the regulated DC power supply for the audio.

The fuse holders were later tied, and 'tidied up'.

Calibration Labelling

(Note: The Blogger editor is full of bugs, and so making editing very difficult at times. For this reason you may see the occasional unusual formatting.)

This article is in principle - finished, but small additions and corrections are still possible. (15/09/2024)