AIWA AD-F770 Dual Capstan Cassette Deck

I've had this deck since about 1999/2000, but seldom used it. About 3 months ago, I decided to play the machine and after a short while realized that the playback speed and stability were not to standard.

Having replaced the belts, the problem of playback 'wow' effect was still problematic - I thought the issue would have been eliminated, but apparently not.

The default 12DC, 2400rpm, CCW (counter clockwise) motor was ageing so I decided to search the web for a replacement. To reduce a long story to a few sentences - I bought several Mabuchi (originally Japanese?) non-brushless motors. At this point it is worth mentioning that the said motors are available on the internet, but could these be Chinese copies, probably?

Rescuing the pulley from the original AIWA motor (spindle ~2mm), I eventually assembled the whole cassette transport together (difficult job) until success was achieved. The transport now runs fine, with the machine running at the correct speed, subject to less than 1% error.

|

| Mabuchi replacement - notibly smaller than the AIWA original. |

Both the new Mabuchi (Chinese copy?) and the original motor have voltage regulators inside, and so it would be quite feasible to repair the olden - perhaps another time?

Motor Speed Calibration

So, how did I achieve calibration? As I don't have a frequency counter I had to resort to other ways.

My only route for now was to use my ant-audio.co.uk Reference Tape with a recorded 3000Hz test tone.

I rigged up the AIWA to playback the tape through the left channel of my amp, and through the right channel a digital reference 3000Hz tone. On playback I listened to both. The two sine waves effectively modulate one-another (ie multiply), and the result produces a beat frequency - the effects of which I can hear. In theory two beat frequencies are produced - the sum and the difference in frequency.

Adjusting the motor speed (via a pot at the motor rear) one can hear the low frequency beat effect speeding up or slowing down. Ideally, the beat frequency should be zero, but I managed to get it to around 1-3 Hz. That's an error of about 3/3000 or 0.1%. Not bad! However, as with motors of this kind, adjustment is very sensitive, and likely to oscillate about the set point within tens of seconds, but as long as the temporary drifts aren't excessive, it shouldn't be an issue. In contrast my Sony TC-K61 has superb speed stability combined with ease of precise adjustment.

Playback Level Calibration

According to the service manual, playback level trimming is adjusted via SFR203 and SFR204 potentiometers.

My ant-audio.co.uk Reference Tape is modulated at 400Hz, Dolby Level, and after cleaning the pots (Servisol) I examined the traces on the oscilloscope. The service manual suggests 580mV from AIWA's calibration tapes - which I assumed were at Dolby Level too? The oscilloscope below now reads ~3.2 divisions x 500mV/per division = 1600mV peak-to-peak. This equates to a rms value of 0.7071x800mV ~ 566mV .... close enough, in fact < 2.5% error.

The truth is - playback level at Line Out doesn't have to be very precise, ±5% should be sufficient?, as long as both Right and Left channels are identical to within small margins, say ±0.5db?

|

| Left trace -top, Right trace - bottom. |

Peak Meter Calibration

Now that the output was calibrated, what about the meters? - they must read DL at this point. Potentiometers SRF701, 702, and 703 were first cleaned and then adjusted from below DL, and then finally 'resting' and stable on DL.

February 2022: Note: adjusting the Left and Right channel meters can be a little tricky!

(April 2025: Go to 'FL Meter Calibration' near the bottom of this long page.)

Record/Replay Head Azimuth

This I already adjusted a while back, but just to check again, I ran the ant-audio.co.uk Ref Tape through the machine and made any (minute) adjustments. Ideally, both left and right channel sine wave traces should line-up (in phase), and display a maximum amplitude or output.

Record Level Calibration

For a deck that supposedly can self calibrate bias, record levels (ie tape sensitivity), and equilization, I found it strange that I could tweak the internal record levels myself, or at least set the machine to reproduce the same output for the same input, ie 0VU in gives 0VU out, or Dolby Level in gives Dolby Level out after invoking the auto-calibration feature. But it seems this was necessary, as this machine was apparently putting too much record level on the left channel by about 2-3dB for Maxell UR tapes, and others.

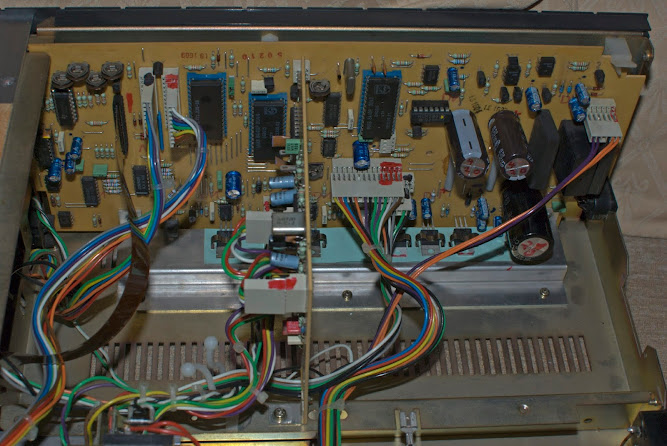

There are two potentiometers to help the machine calibrate - they are SFR401, and SFR402 located as shown (bottom right half of the overall board) ...

Amendment (May 2021) ....

I finally got the F770 to record, and playback 400Hz/1000Hz sine waves to the same level, estimated to be within the region of 0.5dB/1dB, according to the meters. Interestingly, not all tapes were so compliant, which I suspect is down to tape flexibility, the tape pad, and a small amount of head wear! Fast dv/dt transients however, can be a law unto themselves; some +2dB above that recorded.

Much of the calibration work I have done on this deck has not been strickly in accordance with the manual - for one reason, I don't have AIWA's original reference tapes.

Power Supply

There's no doubt that this deck is a good machine, but its circuit layout is complex. The power supply was always getting warm, so I decided to clean the underside of the PS board, and replace three of the regulating electrolytic capacitors which take up less space. Hopefully ensuring better air flow than the previous configuration.

A red marker labels the replaced capacitors.

*********************************

16/03/2021:

Hello everyone,

This page gets more views than any of the other Blog pages, except for the Revox.

So my question to you all is - why are you especially interested in this page for the AD-F770? What problems have you got?

I cannot help you individually, but your feedback would help me to identify common issues with the AD-F770.

Thanks.

************************************

Preparing the Aiwa AD-F770 for Sale

(March 2025)

Recapping the PSU

More new electrolytic capacitors replacing the old.

Due to the congestion of components in the said area, some capacitors where re-situated on the solder side of the circuit board to aid better air flow, and keep the surrounding PSU temperature as low as possible.

New capacitors marked in red or green.

Servicing the Transport

Pinch rollers: Service pending.

PLAY sliding platform: Service pending.

DC Motor/Servo Loading: So far with new belts in, the free-running dc motor/servo currents is approximately 75mA, and in PLAY mode (no tape) is approximately 81mA. These figures are a little higher than single capstan machines - that is to be expected.

Inner Belt Diameter: 76mm x 4mm

Outer (motor pulley) Belt Diameter: 82mm x 4mm

Condition of the Erase/Record/Play Head:

Data Bias Circuit (08/04/2025)

Auto-bias calibration works for Type I, and Type II tapes, but has never worked for Type IV ('Metal') tapes. I've had the deck since 1998/1999, I knew of the fault before I bought the machine.

Chasing the fault is not an easy task, but there are suspect areas from circuit analysis that spring to mind.

Analysis of this circuit is lengthy and so I won't write about it, but on the data bias board there are a set of current sink ICs marked as M54514AP which could hold the key to this problem.

They are employed to facilitate the digital-to-analogue converter, which sets the bias into a unity gain stage buffer OP Amp - IC501. Running the internal counter within the LA6505C IC through data states 00000 to 11111 sets this unity gain OP Amp to an increasing/decreasing voltage output directed to the bias circuit.

Today, the board had its ICs removed, and now I'm awaiting 'new' old-stock M54514AP ICs. Will new M54514AP work? Well, I won't know until I try it.

The M54515AP is a multichannel (7-bit) 'Sink Driver'. Basically, this is an array of output transistors in a 16 pin DIL package which provide two output states: open-circuit, or (near) close-circuit.

The important parameter is the Vce(sat), ie the collector-emitter saturation voltage when the transistor is driven ON. For this design, it must be as low as possible. There are possible alternatives (ULN2003V12) - I may have to look at these later?

The board is also populated with 2SC2001-K NPN transistors which perform a similar task. I may indeed have to replaced some or all of tthese - I have plenty in stock.

Note the 16 pin DIL sockets ready for the 'new' current sink drivers.

The Data Bias circuit was also re-capped, and as can be seen - the solder side looks good!

Now awaiting the 'new' M54514AP ... let's see what happens.

New Old Stock M54514AP

Well, frustratingly these did not work - all three 'NOS' M54514AP chips were dysfunctional, I even tested them 'offline'. These are 'simple' current sink drivers, basically a open-ended transistor collector circuit to which the user adds a 'pull up' resistor between +5v and the collector. Voltage input is applied at the base, being either (roughly) 0v and +5v.

Returning the original M54514AP ICs brought the AD-F770 back to life, and calibrating for Type I, and Type II was possible again, but still no auto-calibration for Metal tapes.

The seller of the 3 M54514AP drivers refunded me, and articulated that he didn't need me to return the drivers! Work that one out!

The 10 x 2SC2001-K NPN transistors on this board were also replaced with 'new' 2SC2001-K.

Successful Data Bias for Metal Tapes

Finally, successful biasing for Metal tapes was achieved, it may not have had anything to do with the possibility of a faulty Data Bias D/A circuit switching.

Note: As I don't have any other formal written references on this deck, I am forming an assumption based on the circuit diagram of the AD-F770, and my interpretation of it ...

It was found that the default setting bias for any tape was too low, and so Data Bias was unable to vary its bias level sufficiently for Metal tapes about these set points.

Re-setting Default Bias

Procedure - set a slow frequency sweep from 1Khz to 10Khz and set the record levels to about -20dB, reference 0VU. (38mV rms at line out)

In my case I used a 1990s TDK D60 cassette tape.

Turn SFR502 and SFR501 fully clockwise.

Turn the AD-F770 to 'monitor' mode and observe the 1Khz to 10Khz trace on an oscilloscope, then turn (right channel) SFR502 anti-clockwise slowly until both levels of 1Khz and 10Khz are equal. Note: Data Bias will use the right channel as a 'testing channel'.

Repeat the same for the left channel by using SFR501.

This will give you a standard bias 'marker' for your standard tape, in my case the TDK D60.

Test the deck's auto-calibration, Data Bias procedure will use your standard as a reference, and will alter the bias accordingly.

With this procedure finished, both Type II, and Type IV tapes should auto-calibrate without problems.

FL Meter Calibration

The service manual's description on calibrating the FL meters on the AD-F770 is a little ambiguous.

My interpretation is as follows ...

Take-up Pinch Roller Replacement (05/05/2025)

At least that was the intention.

I learnt that the roller is 13.5mm diameter, the steel pin is 2mm, but the width of the roller is 7mm. I only had 8mm in my stocks, so may be I'll order a new roller?

The shaft needed to be cleaned, it was quite 'sticky'.

Supply & Take-up Pinch Roller Mechanisms:

Both removed and cleaned - old grease was sticky. Cleaned with switch cleaner and cotton buds. Movement - much easier.

Revisted: DC Motor/Servo Loading

So far with new belts in, the free-running dc motor/servo currents is approximately 45mA, and in PLAY mode (no tape) is approximately 54mA. Much better figures than earlier.

Inner Belt Diameter: 76mm x 5mm

Outer (motor pulley) Belt Diameter: 80mm x 5mm

Mean Wow/Flutter: ~ 0.04x% to 0.05x% wrms.

SOLD. May 2025.

(Article is subject to corrections, alterations, and updates without notice.)