The NEAL 102 Cassette Deck

I bought this on 26th December 2022 and received it before the New Year. It was advertised as ‘faulty’ and indeed upon receipt of it, it was!

Original Advert

On inspection the deck was wired to the 13 amp plug without the earth connected, and what appeared also to be a blown fuse.

The first task was to establish why the fuse had blown which lead me to initially de-coupled the audio board from the power supply. All that now remained was to investigate the integrity of the transformer, fuses, and the 115v induction motor.

Power Supply & Induction Motor

Disassembling the motor it became obvious that the motor rotor had seized, probably as a result of dried grease and oil? Freeing the rotor wasn’t difficult and so this and the rest of the motor was taken apart.

Neither the 500mA fuse from the primary winding circuit, or the audio board fuse had blown, so I could assume no short-circuit had taken place. Not sure why the mains fuse had blown though!?

Later, with the audio board isolated from the power supply, the motor and transformer were 'checked over' to confirm all was well.

The first task was to establish why the fuse had blown which lead me to initially de-coupled the audio board from the power supply. All that now remained was to investigate the integrity of the transformer, fuses, and the 115v induction motor.

Power Supply & Induction Motor

Disassembling the motor it became obvious that the motor rotor had seized, probably as a result of dried grease and oil? Freeing the rotor wasn’t difficult and so this and the rest of the motor was taken apart.

Neither the 500mA fuse from the primary winding circuit, or the audio board fuse had blown, so I could assume no short-circuit had taken place. Not sure why the mains fuse had blown though!?

Later, with the audio board isolated from the power supply, the motor and transformer were 'checked over' to confirm all was well.

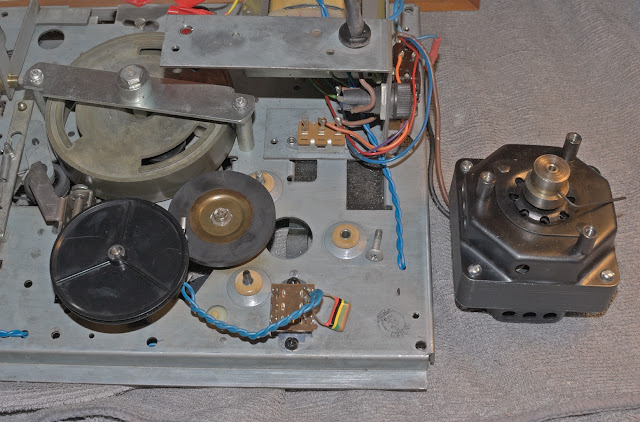

Understand too, that at this time I removed the large flywheel, cleaned and lubricated it. The idler gear (in the middle) was also cleaned with denatured alcohol and later with Rubber Renue. All other moving parts were cleaned with either denatured alcohol or Servisol Super 10 (or equivalent) switch cleaner.

Motor field windings, and Rotor.

Rotor in Isolation

The motor current on driving the idler gear and large flywheel was measured at 138mA AC (rms). This is a figure I would expect; anywhere between 75mA to 150mA would not be unreasonable.

The NEAL 102 came with the standard original user manual, various other literature and a ‘Service Instruction’ manual. The latter appears to have been a temporary document until the official Service Manual was printed? I can only assume that this was an early Neal 102 MKI; serial numbered at 2291.

The power supply circuit diagram is shown with some measured voltages; these were later done 'under load' conditions.

The power supply circuit diagram is shown with some measured voltages; these were later done 'under load' conditions.

There are no voltage markings on this Service Instruction circuit diagram.

At this moment, ac supply and motor circuit integrity was the main focus of attention.

Much later in the restoration project the transformer was tested ‘offline’;

I initially found it difficult to believe that the audio board dc voltage was designed to be about 40v!?

Measurements ‘offline’ confirmed the above SI circuit diagram was correct.

I subjected the transformer to a simple signal generator where I set the frequency to 50Hz (UK mains frequency), and the input to the primary to 2.40v (two point four) ac rms. Within this ‘safe’ environment, the results were:

Primary Windings: Brown = 2.40v, Red = 1.2v, and Magenta = 0.18.

Secondary Windings: Yellow-Yellow = 0.48v, and the other seconary winding was 0.11v AC (rms).

With this, I knew the winding ratios were correct, the transformer was then returned to the deck, the motor re-connected and tested. This side of the circuit was stable.

Motor to Idler Alignment

With the power supply switch on, and observing the motor pulley, idler, and flywheel in action, the line taken by the idler and the pulley (set for 50Hz operation) was questionable.

A very small metric (1.7mm) allen key was needed to loosen the pulley from the motor spindle. Moving the pulley up and down the motor shaft wasn’t easy; I’m not sure that is by design? Although there is no thread on the motor shaft, a screwing action seemed to be required to move the pulley up and down the motor axial.

Later, idler to motor pulley alignment was improved; here observe that the idler was possibly too low?

Circuit Board Initial Checks

The audio board was removed and checked for any obvious short circuit. The procedure was to connect the (unknown at this time) 40v dc rail and earth point to a variable DC, current limiting power supply.

With a regulated variable power supply the initial current limit was set to a low figure of about 50mA, and then the dc supply voltage gently increased observing the current demanded by the audio board.

Here also, I gently opened up the current limiter and saw all was good, no obvious short circuit!

The audio board was then returned to the system, and the deck could be generally tested to see if the NEAL 102 was ‘basically working’.

The answer to that question was – yes it was.

The deck was indeed playing back tapes, but the original pinch roller has disintegrated, which rendered it useless from a fidelity point of view.

Pinch Roller & Mechanism

With the deck disassembled again we can see the ‘floating’ pinch roller and its assembly. A most unusual design which seems to have been replaced in other and later versions involving this Wollensak based machine?

The pinch roller was clearly beyond repair and so a complete replacement was necessary; that is both the pinch roller and the mechanism that guides it.

At first, a replacement seemed challenging until a makeshift idea of utilising an old Sony mech became possible, complemented with a 2mm shank steel rivet and temporary pinch roller.

However, this wasn’t as easy as it first appears. Underneath the roller axis was a ‘resting’ post used by the previous assembly which would have to be removed if the ‘new’ pinch roller was to be centred in line with the cassette tape. The complete head assembly had to be taken out to access the rivet-like fitting for this post or boss.

The rivet-like finish that secured this boss was ground down using a Dremel, and the boss was slowly taken out with pliers. Care was taken not to distort the head assembly platform.

A strong, 'hold down' spring underneath had to be temporarily disengaged from the sliding mechanism, and was held ‘suspended’ with string as shown; a ‘neat’ little trick worth remembering!

There were still two outstanding issues to be resolved here: the base of the record head ‘catches’ the swinging mechanism if the roller is withdrawn far enough in, and a ‘stopper’ needs to be added to stop the pinch roller from springing out beyond the capstan.

At the time of writing, only the ‘stopper’ issue has been resolved; roller mech and record head base conflict doesn’t occur unless I exaggerate pinch roller withdrawal. The ‘stopper’ is somewhat crude, but it works well; a simple loop of insulated wire!

New pinch roller, NOS mech, and a new record/play head fitted.

Audio Circuit Board

A warning to anyone who wishes to restore a NEAL 102 cassette deck second hand: there are no component markings on the circuit board; none! Which translates that - a careful, and systematic approach is 'a must' to replacing all electrolytic capacitors. It is so very difficlt to follow a circuit diagram and an actual PCB without guidance.

It took several hours to complete the full electrolytic capacitor substitution.

Later I intend to minimalize ‘wear’ on the main circuit board by attaching a simple home-made ‘8 line’ cable extension to the original design. This will enable me to remove the main board and the selector switch much easier without fatiguing the 8-line solder connection between the two

Correction: As I found out the other day, this is not the case - you can keep the Mono/Dolby/Cro2 switch soldered on to the main board and remove the whole main board quite easily by unscrewing the plate that 'mates' the Mono/Dolby/Cro2 switch to the main chassis. (9/02/2023)

Removed Selector Switch.

NEAL 102 Cassette Deck Alignment

Finally, after many hours of work, I arrive at the final stages of this restoration project. With a new record/play head in, a series of alignments need to be carried out.

De-magnetisation of all Heads: Easy.

Record Head Track Height: Required since a new and different head is to be used. I will use my home-made 3Khz test tone recording made on the Nakamichi DR10.

The procedure is to playback the 3Khz test tape, azimuth-align the tape (at 3Khz) and write down the amplitude for each amount of shims inserted. I had several spare shims, and here just 3 shims returned the highest output. The shims are very thin, perhaps around 20µm?, I'm not certain.

Record Head Azimuth: Easy, currently using an ABEX 10Khz alignment tape.

Playback ‘PB’ levels at 400Hz: Adjust to reflect Dolby Level to meet with Service Instructions requirements; SI quotes 100mV at line out on playback of a Dolby Level reference tape.

Record Level: Normally a permanent adjustment for a particular tape. However, in this case a temporary adjustment is made that facilitates both left and right record levels to be equal on record. Fine tuning for a specific tape will be undertaken later; perhaps for TDK D?

Playback EQ (de-emphasis): There is no NEAL (or NEAL-Ferrograph) factory alignment playback (PB EQ) tape that I can use, but from tests involving this new head, suggest that the level of de-emphasis (Playback EQ) is as strong as several Sony decks I have. (See note (C1) below)

With the new head in place, playback EQ levels between 333Hz and 10Khz from a Nakamichi DR10 home-made ‘reference’ suggest a reduction to just 35% at 10Khz compared to the level at 333Hz.

This translates to about -9dB drop between the two said frequencies.

(See note (C1) below)

Note: This NAK DR10 reference tape was recorded at -10dB, ref Dolby Level. This tape is only used for comparison, or to compare other 1970s (pre-Prague 1981) machines with each other.

Allowing for small measurement errors and general ‘old’ deck ageing misalignments, differences of between -4dB and -9dB have been recorded from my Sony, Akai, and Sansui decks.

Bias Setting: Measurement of the bias ‘carrier’ at the record head when the old head was in place was approximately 29v peak. The same voltage was noted with the new head fitted, but on initial tests, this was insufficient as playback frequency response rose steadily after approximately 1Khz. Increasing the bias voltage to 35v peak brought down this high frequency drift, and playback was reasonably flat to 10Khz. Final tweaking will have to done later when all issues are resolved.

(See note (C1) below)

Note: This NAK DR10 reference tape was recorded at -10dB, ref Dolby Level. This tape is only used for comparison, or to compare other 1970s (pre-Prague 1981) machines with each other.

Allowing for small measurement errors and general ‘old’ deck ageing misalignments, differences of between -4dB and -9dB have been recorded from my Sony, Akai, and Sansui decks.

Bias Setting: Measurement of the bias ‘carrier’ at the record head when the old head was in place was approximately 29v peak. The same voltage was noted with the new head fitted, but on initial tests, this was insufficient as playback frequency response rose steadily after approximately 1Khz. Increasing the bias voltage to 35v peak brought down this high frequency drift, and playback was reasonably flat to 10Khz. Final tweaking will have to done later when all issues are resolved.

Bias Frequency: The period of the bias frequency was measured at be approximatey 2.7 x 5µS, ~ 1000000/(2.6 x 5)Hz, or ~ 77Khz. I will probably confirm this later.

Measuring Bias Voltage at the Record Head.

(Oscilloscope probe impedance ~ 10MΩ for accurate measurement)

(Oscilloscope probe impedance ~ 10MΩ for accurate measurement)

Record EQ (pre-emphasis): It is not often you see a deck that allows the technician to ‘tweak’ the rise in frequency emphasis above mid-band (approx 300Hz .. 500Hz) frequencies, but the NEAL 102 allows just that!

This emphasis can clearly be seen on the VU meters; expect a standard rise of about 10dB/15dB from about 500Hz to 10Khz. Altering the relevant potentiometers, I was able to adjust this with ease to roughly ±3dB of the 10dB quoted above.

This emphasis can clearly be seen on the VU meters; expect a standard rise of about 10dB/15dB from about 500Hz to 10Khz. Altering the relevant potentiometers, I was able to adjust this with ease to roughly ±3dB of the 10dB quoted above.

|

| NEAL 102 VU Record Level Meter Current Readings (Measurements taken from the VU meter circuit, small errors in measurment are probably present) |

Shown above is the variable audio signal voltage amplitude as driven into the record head. It is this curve that will be followed, or very close to it.

Record head impedance will naturally attenuate head current with frequency (basic electrical engineering theory), therefore for near-constant, or a controlled audio signal current (hence near constant magnetic flux), the signal needs to be emphasised in this second half of the graph, hence the term 'pre-emphasis'.

I have taken similar measurements from other cassette and reel to reel decks, but this time at the record head! However, with this approach it is difficult to obtain accurate results, as the audio signal is so small in comparison to the bias 'carrier' envelope. Oscilloscope triggering also becomes difficult.

Calibration

For this NEAL 102, calibration is better done at the back; solder side of the circuit board. The Service Instructions are slightly confusing as they illustrate the potentiometers (and transistors) from the component side.

|

| A permanent marker aided easy access to the calibration potentiometers. |

Performance

If anyone has read the old sales brochures for the NEAL 102/103 series, you'll appreciate that this deck back in 1974 had a good specification; cassette players and decks were still in their infancy. However, let's not get carried away and expect 'Revox/Nakamichi performance'!

Below this paragraph, I hope to add some performance findings regarding this apparently early version of the NEAL 102.

Wow & Flutter: Firstly, I had to remove the supply reel belt to the counter, as sometimes the counter sticks creating unpredictable variable back tension.

So then, with the cheap, temporary pinch roller fitted, wow and flutter as measured from 200 samples from the WFGUI.EXE log file was:

Mean Value: 0.09% DIN, (The standard deviation was 0.009)

So then, with the cheap, temporary pinch roller fitted, wow and flutter as measured from 200 samples from the WFGUI.EXE log file was:

Mean Value: 0.09% DIN, (The standard deviation was 0.009)

Mean Speed Error: -0.62%

Test tape: ABEX 3.15Khz Full Track.

Frequency Response ('Normal Tape'/1980s TDK D): Not yet formally done, but observing playback of white noise at around -20dB (ref: Dolby Level), the original specification of 35Hz ... 12,000Hz is about right. Although it looks like the 12,000Hz figure will be extended based on observations to around 12,500Hz to 13,000Hz. The Fast Fourier Transform profile also shows mains hum and its harmonics, but that is to be expect when we record at only -20dB!

Other Images

Other Images

VU Meter Lighting: 6.3v rated filament lamps in series,

running off the second 10.5v/11v ac secondary winding.

NEAL 102 under general testing with the original record head.

running off the second 10.5v/11v ac secondary winding.

NEAL 102 under general testing with the original record head.

All working!

The fact that NEAL (North Easy Audio Ltd) provided such an array of performance tweaking options tells us that this was a serious machine for the serious audio enthusiast. Back in the 1970s, I remember NEAL, but only in adverts and in particular The HiFI Year Book 1976. Back in 1974/1975/1976, the NEAL 102 and 103 models were far too expensive for me to buy, I could only dream!

Small Fixes:

- 18/02/2023:

I sanded-down the edge of the pinch roller mechanism so that the mech can

swing back and forth without clashing with the base of the record head.

Note - the head replacement is merely a DYNY62 we see on ebay and other places; probably Chinese made? I still have the original record head for this machine; should I get it lapped?

|

| Note also: the mechanism 'stopper' is somewhat crude, but it works and doesn't interfere with pinch roller pressure. |

Outstanding Issues:

- DIN input distorted and overly sensitive, DIN output however, is fine.

Corrections: (C1) I quoted a '-3dB' or '-4dB' reduction earlier, that was not correct.

This blogger page will be updated allowing for corrections and additions without notice.

19/01/2023

cassettedeckman@gmail.com

No comments:

Post a Comment