Purchased off ebay UK, it was clear that this machine needed attention. As always, buying an old machine is always a risk, but I think this risk was worth it since the price was low.

On inspection, the left meter dial loading spring had buckled, and the right meter dial loading spring had also buckled, but this meter had also developed an 'open circuit'. Both meters were beyond restoration, so an alternative had to be found.

I had some ideas regarding digitizing the VU meter display, but realizing this was going to be difficult and time consuming, it was decided to drop the idea and search for an exact-fit VU meter replacement.

The idea of swapping old for new numeric display inserts crossed my mind, but soon realized that the two scales didn't match very well, especially around -10dB and -20dB.

The next problem was to establish suitable alternative light. The previous configuration projected light from behind the original meters, but this proved unsatisfactory since the display appeared too vibrant, almost fluorescent in appearance.

Illumination is from under the meters.

(Long exposure photography)

Illumination is still from under the meters.

(Flash exposure photography)

135uA FSD, and 650Ω internal resistance.

VU Meter Lighting and Assembly

Once the new fascia was removed, and the former re-employed, the next task was to find some suitable lighting. There was indeed a degree of trial and error methodology at work here, but finally settling for the following configuration.

Here strip-LED-lighting cut to length, wired, and a suitable DC voltage drop from the unregulated motor DC supply, to give just the right amount of lighting. All LEDs are deliberately running at much less than rated current of 20mA, typically about 5mA - 6mA for each of the six LEDs.

Strip-LED is at the base of both meters.

into the two secondary winding circuits, for

(a) DC motor and 'new' LED lighting, and

(b) Audio/bias PCB.

- Additional Fuses: Quick Blow (500mA provisionally)

- Smoothing Capacitor C304: was 2200uF, now 3300uF, voltage rating is higher than 25v.

- LED Circuit Series Resistance: 330Ω, 2W rated, but even a 1 watt rating will be okay.

Take-up Spool Issue

There was insufficient torque developed by the take-up spool which was accounted for from the lack of driver-to-idler friction. This was resolved by putting the cassette deck into Play mode, 'roughing up' and thus 'cutting' into fresh rubber, the idler tyre with fine sand paper. Any debris resulting was cleaned up, and the idler was later carefully cleaned with IPA, and then later again treated with Rubber Renue.

All other gears and frictional pulleys were cleaned, again with IPA.

Record/Playback Head

The record/playback head works well, but does show signs of wear on its face. Any resetting of azimuth is out of the question, since the wear grove will probably influence any future azimuth adjustment. So either the head will be lapped, or a replacement will be fitted.

At the time of writing, the original head has been removed.

Head inductance estimated prior to lapping: L-Ch ~ 90mH, R-Ch ~ 83mH. All estimated at 1Khz.

To be lapped.

than this photograph is suggesting.

Lapped Record/Playback Head

Although I have a small stock of record-playback heads with Metal tape capability, and so could have directly replaced the head, getting the original head lapped was the preferred option. The head was successfully lapped by https://www.summertone.com.

Head Height

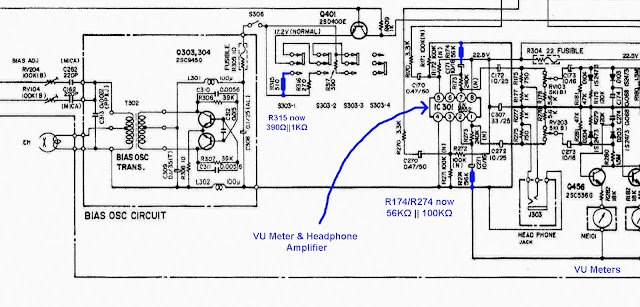

According to the service manual R315=510Ω, but in its place was 390Ω? This was the reason why I could not bias Normal (Type I) tapes properly.

Since I have a large stock of 470Ω (1/2 watt) resistors, these proved to be a suitable replacement. The result of this was that I could now bias the deck so that provisionally the record/playback response goes past 10Khz to >16Khz at -3dB, reference 1Khz.

Returning to the head height issue, it was clear that the inner most channel (the right channel) was too high causing some low cross talk interference with the adjacent right channel. Although this cross talk was low, it could be sometimes heard if one side was unrecorded.

After thinking about this, it was decided to lower the plastic head height post on the head assembly in very small increments. Sanding down that said post down by several tens of microns was seemingly the only option?

New Rec/PB Head

There's no doubt that this was proving to be successful as the cross talk lessened each time. However, it came to the point where I decided to change the head completely - this time cross talk was so low it was barely detectable. Here subjecting the tape to a 333Hz test tone at about +10dB (Ref: Approx 160 nWb/m DIN), the tone could just be heard in the right channel buried deep into the noise - this was as good as it was going to get.

With the new head finally soldered in, the correct head height, and azimuth had to be established. This was achieved using my home made Nakamich DR10 made 3Khz reference tape. The process of establishing correct height is a time consuming process of trial and error where various or multiple shims are placed between the head post and the base of the head platform on the right hand side. Here in this initial photograph, there no shims inserted.

With the plastic head height post 'sanded down' by a fraction of a mm, the highest output was achieved using just the one (ironically original) shim. Azimuth was set using an ABEX 10Khz full track reference. The entire head and path were demagnetized before reference tapes were used. Many of the calibration settings that followed were still only provisional.

Later I will have to carefully ream out a groove in the head support base holes of about 0.5mm ... 1mm in the direction of forward head movement to effectively lessen head depth during Play.

Revised Head Depth

With the locating holes on the platform of the record head 'reamed' slightly to facilitate less head penetration during Play/Record, and with the original shim in place, finally thoughts turn towards calibrating this machine.

Provisional Frequency Response

With the bias circuit modified again to its original factory state from the changes previously mentioned above, a frequency record/response curve was determined using a TDK D46 cassette tape.

On the application of White Noise during record at approximately -20dB (Ref: Dolby Level in this case), the playback plot is shown below.

PB response is approximately to 15,000Hz,

at -3dB, reference: 1Khz.

Total Harmonic Distortion (on TDK D46)

For an estimation of THD (Total Harmonic Distortion) at 1Khz, a recording was made at Dolby Level, then played back at a level of +1dB above Dolby Level we examine the following Fast Fourier Transform plot -

As can be seen, only the 3rd harmonic dominates, which is very convenient.

This greatly simplifies the expression for THD.

Generally Total Harmonic Distortion is defined as ...

Where V1 is the fundamental frequency, and V2, V3, V4 etc, are harmonic distortions of V1.

However, since it is only the 3rd harmonic we are considering, this simplifies to just THD ~ V3/V1 or THD ~ V@3Khz/V@1Khz.

From the Fast Fourier Transform capture, the Third Harmonic lies at approximately -12dB below the 1000Hz test tone which is at +36dB on this scale. Therefore, this difference is ~ -48dB, and so the THD can be estimated from ...

or

10^(-48/20) = V@3Khz/V@1Khz

VU Meter Amplifier Revision

The gain of the AN6552 OP Amp was modified slightly to allow the VU Meters to be calibrated to '0' at Dolby Level. This small revision gave me about an extra 3dB of voltage output for the meters, which is what was required.

|

Wow & Flutter and Speed Drift

With a belt 70-72mm in diameter, and 3.5mm in width, early wow and flutter figures were determined over a period of about 9 minutes. The belt was from my stock, not necessarily the one I'll finish with, so it's provisional. (Later discovered that 4mm wide belts tend to get thrown off - they are simply too wide!)

The wow and flutter, and target speed figures are based on a ABEX 3.15Khz full track test tape. Target speed is 3150Hz, the deck was set to around 3155Hz, and drifted to an estimated 3165Hz in about 10-15 minutes, that equates to 0.16% and 0.48% fast respectively, assuming the ABEX tape is precise.

DC Motor Swap

Despite the fair-to-good wow and flutter figures I could still hear occasional very slow-moving speed changes, something that was not going to be detected by the wow and flutter program WFGIU.EXE.

It was decided to disassemble the original and swap it for a NOS Mabuchi ED-550L 12DC, 2400 rpm motor with internal speed controller.

Since sourcing a 2400 rpm, 12V DC brushed motor with 2.5mm shafts is very difficult, the problem here was matching a 2.5mm centered-hole pulley to a 2mm motor shaft. Some reliable adaptation had to made between the new Mabuchi 2mm motor shaft and the 2.5mm centered-hole pulley.

Experimentally, a 2.5mm outer diameter brass tube was cut to length and this was carefully 'hammered' into the original pulley. Next this new adaptation had to be fitted to the 2mm Mabuchi motor shaft. It was a close fit, but not tight enough, and so experimentally the motor shaft was bonded to the inside of the brass tube, which already had the pulley fitted.

After allowing 10 hours for the bond to 'cure' (24 hours recommended), the NAD 6040 was temporarily tested for speed stability, and wow and flutter.

New Mabuchi 12DC, 2400 rpm Motor.

Original pulley fitted via 2mm to 2.5mm adaptation.

So far - very stable, pulley movement is very concentric.

Note: the glue expands as it 'cures'.

Original Pinch Roller Returned to the NAD 6040

Wow and flutter figures continued to be too variable and unpredictable for my liking, and later they even increased significantly from the above figures.

Observing close-up the 'new' pinch roller, I discovered that the said roller's rubber surface was oscillating back and forth along the line of the capstan as it turned!

So again, I had to open up the deck and re-fit the original roller, followed by 'sanding down' the roller, and then cleaning off the residue with IPA.

What happened next surprised me - the wow and flutter figures fell to under a mean value of 0.087% wrms. It seems the newly bought roller was substandard!? (No, I later discovered that the pinch roller 'tyre' was not seated correctly on its rim, the imperfection was tiny, but enough to cause wow/flutter disturbances)

Original (and 'sanded') Pinch Roller Returned

Mean wow & flutter: ~ 0.087% WRMS.

Observe: increased dispersion in wow/flutter with time.

Possible cause - no apparent back tension on the NAD 6040?

Therefore, as the supply reel 'empties out' it loses mass,

thus less inertia, and less 'drag'.

Finally, the restoration is complete, a summary may follow later.

cassettedeckman@gmail.com

*This write up may be subject to alterations, corrections, and additions without notice. 24/03/2024

Revision: (08/04/2024)

.jpg)

.jpg)

-1.jpg)